Here’s a breakdown of the key factors:

1. Stiffness

The stiffness of the diaphragm material directly impacts its ability to respond to high-frequency signals. A stiffer diaphragm (like beryllium or titanium) is better suited to produce higher frequencies because it can maintain a more rigid shape under vibrational forces. This results in less distortion and more precise movement, leading to a more accurate high-frequency reproduction.

On the other hand, a less stiff diaphragm, like silk, tends to exhibit more flexibility. While this can help with smoother midrange frequencies, it also introduces a greater degree of nonlinearity and distortion at higher frequencies, which can affect high-frequency response and create a softer sound.

2. Speaker driver diaphragm stored Energy Dissipation

What kind of energy are we talking about?

The primary speaker driver energy comes from the coil and is transferred to the diaphragm. Part of that energy is transferred from the membrane to the air as direct sound. A portion of the energy remains stored in the diaphragm. This energy is released over time as parasitic oscillations that produce sound waves that are actually distortion. The duration and intensity of these parasitic oscillations depends on the mass of the membrane and the type of material it is made of. Greater mass means more stored energy and more parasitic oscillations.

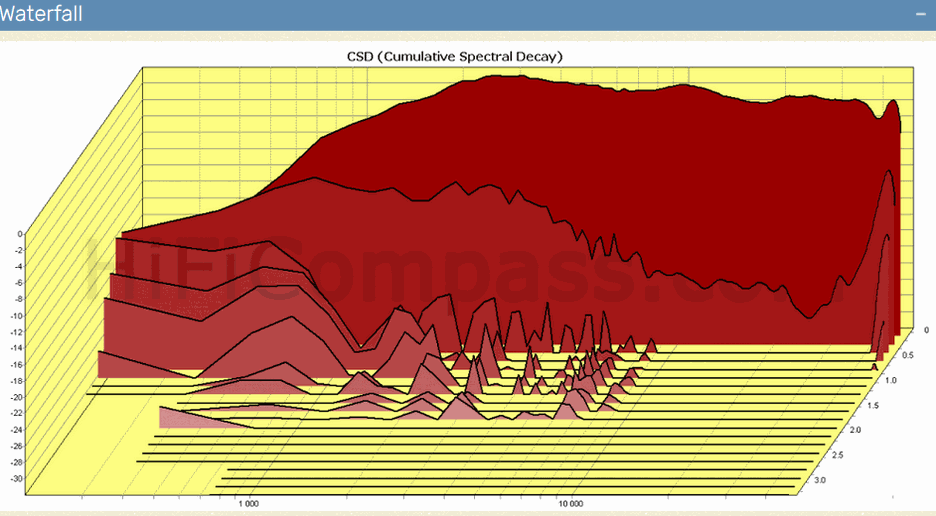

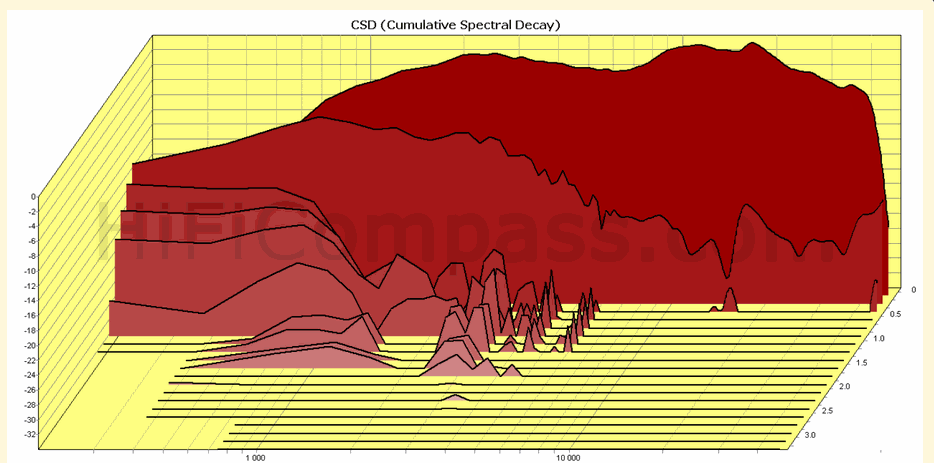

Silk releases energy more slowly. This causes longer period of energy retention in the diaphragm, resulting in a warmer sound. On the CSD plot which you can see below, this will appear as a slower decay of amplitude at higher frequencies. Silk absorbs more energy and releases it more slowly.

Beryllium releases energy more quickly. This means it doesn't retain energy as long, so resonances decay faster, and the sound becomes sharper and more precise. On the CSD plot which you can see below, this will appear as a faster decay of amplitude, with less energy retention time. Beryllium absorbs less energy and releases it more quickly

Conclusion:

· Silk has lower stiffness and higher damping, meaning it absorbs more vibrational energy within the diaphragm itself. This energy is then released slowly, resulting in longer resonance durations and reduced efficiency in transferring energy into sound waves.

· Beryllium, on the other hand, has high stiffness and relatively low damping, so it transfers most of the vibrational energy directly into the air, creating a more precise and efficient sound with minimal internal energy retention.

How can we measure that?

The Cumulative Spectral Decay (CSD) plot shows how long a particular material (or diaphragm) retains internal energy, which is directly related to the material's damping. The different plots at times like 0 ms, 0.5 ms, and 1 ms in a CSD or waterfall plot represent how the energy at each frequency band dissipates over time after the initial impulse. The shape of the decay and the presence of lingering energy are indicative of the material properties of the diaphragm.

What This Means for Silk vs. Beryllium Tweeters:

· Beryllium: Often show sharper, more defined peaks and quicker energy release.

You will likely see sharper, more distinct peaks at specific time intervals, especially at higher frequencies. These are often due to ringing or resonance, and the energy will decay faster overall, particularly in the low- to mid-frequency range. High-frequency ringing can persist for a short time before dissipating.

· Silk: The decay tends to be smoother and more gradual. You will see broader, smoother decay curves without as many sharp peaks or pronounced resonances. The energy decay is more gradual, especially at lower frequencies, and ringing will typically be less noticeable. The energy will fade off in a more continuous fashion.

3. Resonance Characteristics

Resonant Frequency of Tweeters

The resonant frequency (f₀) of a tweeter is typically the lowest frequency at which the diaphragm naturally vibrates without external force. This depends on the diaphragm's mass, stiffness, and the compliance of the suspension. For most tweeters:

- Resonant Frequency Range: 500 Hz to 1.5 kHz.

- Soft dome tweeters (e.g., silk or textile): Around 500 Hz to 1 kHz.

- Hard dome tweeters (e.g., beryllium, aluminum): Typically 1 kHz to 1.5 kHz, due to their lighter and stiffer construction.

Tweeters are usually crossed over well above their resonant frequency to avoid distortion, often above 2 kHz.

Each material exhibits its own resonance behavior, which significantly impacts the overall sound quality. The diaphragm's resonant frequency is a critical parameter. Stiff materials like beryllium tend to have higher resonant frequencies.

Flexible materials, such as silk, have lower resonant frequencies, and their resonances may overlap with the midrange and treble, potentially introducing coloration or warmth.

Here's how it impacts sound characteristics:

1. Frequency Response at Low Frequencies

- The tweeter's resonant frequency marks the point where its natural mechanical resonance occurs, often at the low end of its usable range (e.g., 500–1,500 Hz for most tweeters).

- If a crossover is not properly designed to attenuate frequencies near or below the resonant frequency:

- Boosted Output: The tweeter may produce a peak in response around the resonant frequency, adding unnatural brightness or harshness to the sound.

- Distortion: Excessive movement near resonance can cause the diaphragm to behave non-linearly, introducing audible distortion.

![]()

2. Transient Response and Clarity

- Near resonance, the tweeter's diaphragm tends to "ring" or continue vibrating after the input signal stops. This ringing can blur transient details and affect the clarity and precision of high-frequency sounds.

- Proper damping reduces this ringing, but an underdamped tweeter can sound overly bright or metallic.

3. Harmonics and Tonal Coloration

- Resonance can introduce harmonics that add a "color" to the sound, making it less neutral.

- Tweeters with high resonant frequencies are less likely to interfere with the midrange, leading to smoother and more natural tonality.

4. Surface Texture and Shape

The surface texture and shape of the diaphragm also affect how sound waves are dispersed. Silk membranes, for instance, tend to exhibit a soft, diffused sound due to their micro-textured surface, which scatters sound waves more evenly. This results in less directivity and often a more pleasing or natural sound, especially in the midrange.

Beryllium, with its smooth and rigid surface, tends to produce more focused sound with greater directionality, which can enhance clarity and detail but also emphasize harshness in some cases. The smoothness of the beryllium diaphragm leads to more direct propagation of sound, especially in the treble region, but can sometimes make the sound feel too clinical.

5. Break-up and Nonlinearities

Break-Up Frequency of Tweeters

The break-up frequency occurs when the diaphragm no longer vibrates as a rigid body and starts to exhibit flexural modes. This frequency depends on the material's stiffness, mass, and geometry. For most tweeters:

- Soft Domes (e.g., silk, textile):

- Break-up can start around 10–15 kHz but often has low impact due to the damping properties of soft materials. The energy dissipates gradually, leading to less audible distortion.

- Hard Domes (e.g., beryllium, aluminum, titanium):

- Break-up typically occurs at much higher frequencies, aluminum around 20–30 kHz, beryllium around 35-45 kHz

- In most cases, hard dome tweeter break-up frequencies are above the range of human hearing (20 kHz) but can still influence sound quality due to intermodulation distortion or phase issues. When the membrane enters modes of vibration at the break-up frequency, harmonic distortions may occur, some of which may fall within the audible spectrum. Break-up can cause sudden changes in the phase response and nonlinearities in the frequency response. This can be perceived as harshness or an unnatural tone in the high frequencies.

6. Interaction with the Surrounding Structure

The diaphragm is just one component of the driver system, and its interaction with the suspension system, magnetic structure, and enclosure all contribute to the overall sound. Softer diaphragms like silk can integrate well with suspension systems that require more compliance, resulting in lower distortion but reduced high-frequency extension. On the other hand, harder diaphragms like beryllium can demand more from the suspension to compensate for the rigidity of the material, which can result in a stiffer, more focused sound.

![]()

Conclusion

The material and mass of the diaphragm influences the sound color and tonal quality of a speaker. These properties dictate how the diaphragm moves in response to signals, how it handles energy, and how it produces sound. Silk diaphragms tend to offer smoother, more plessent sound with less harshness, but more colored, muffled and more muddy sound, especially in the midrange. While beryllium diaphragms offer sharper, more extended high frequencies and can produce a cleaner and less colored tone, due to their low mass and high stiffness.

Regardless of the fact that differences in diaphragm properties can be scientifically explained and proven through measurements, some of these material properties are difficult to measure, and it is especially challenging to interpret the measurements and extract all the diaphragm characteristics related to the specific color and tonality. It is necessary to conduct listening tests to identify all differences in the color and tonality of the sound. A combination of measurements and listening tests gives the best results.

All these

considerations apply to other types of materials, not just silk and beryllium.

Tihomir Haralović, M.Sc. in Physics

Zagreb, 29 December 2024